With our large wealth of experience in the fields of process technology, GMP design, plant engineering, and qualification, we assist you as a competent partner: from the development stage right up to the production phase.

Apart from the use in the pharmaceutical sector for the manufacturing of, for example, granules, pellets, implants, or contraceptive vaginal rings, Leistritz technology comes also into effect in the following fields:

- Nutraceuticals, for example in the manufacturing of functional food or dietary supplements (such as the incorporation of omega-3 fatty acids or amino acids into the excipient)

- Cosmeceuticals, for example in the incorporation of active ingredients or vitamins

- Foods, for example the incorporation of starch, the manufacturing of meat substitutes or rice crisps

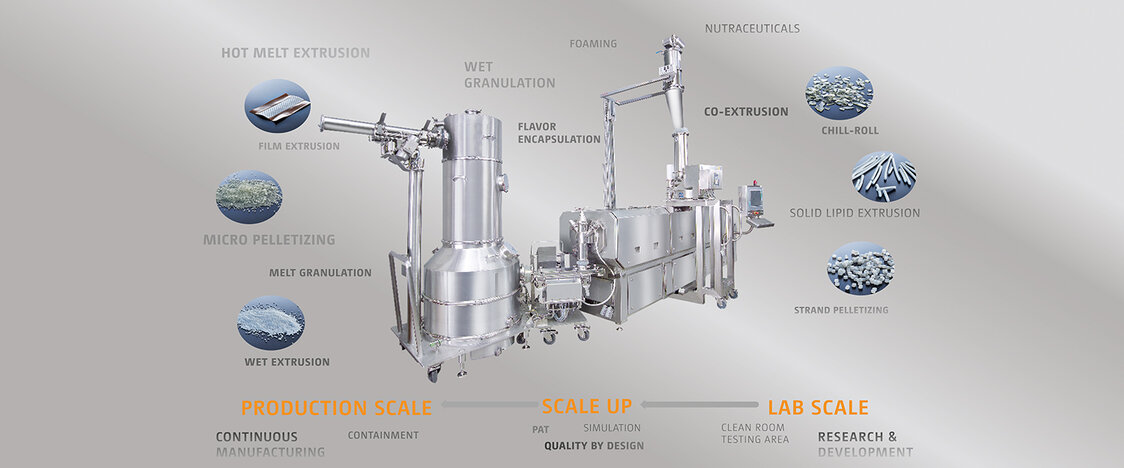

The Processes

Hot Melt Extrusion

In most cases, hot melt extrusion is used for the dispersing of solids. The reason for this is the usage of hardly soluble active ingredients, BCS class 2 and 4, which obtain a significantly improved bioavailability through the dispersing of solids. Also, prolonged-release formulations can be produced in this way. The modular design of the twin screw extruder, together with a vast experience in the field of process engineering, is of enormous benefit. All common pharmaceutical polymers can be processed.

Granulation

Leistritz twin screw extruders enable various continuous granulation processes. Due to their modular design, both hot melt granulation and wet granulation can be accomplished. Leistritz extruders can be integrated perfectly into a continuous production plant. By using suitable dies, hot melt extrusion can be accomplished as well, which is completed in a subsequent spheronization process.

Solid Lipid Extrusion

Solid lipid extrusion is done a few Kelvins below the lipid's melting point. It is a solvent-free process and also suitable for temperature-sensitive products. We offer various downstream units for this process.

Contact us

Albrecht Huber

Head of Pharma and Life Science

Leistritz Extrusionstechnik GmbH

T+49 911 4306-788

Matthias Reinwald

Sales New Machinery

Leistritz Extrusionstechnik GmbH

T+49 911 4306-619