The so-called multifunctional products are combination products loaded with an active ingredient in order to transport it to the target location or to influence its release. Examples are drug-coated coronary stents, catheters, contraceptive or dental implants, vaginal contraceptive rings, or transdermal patches.

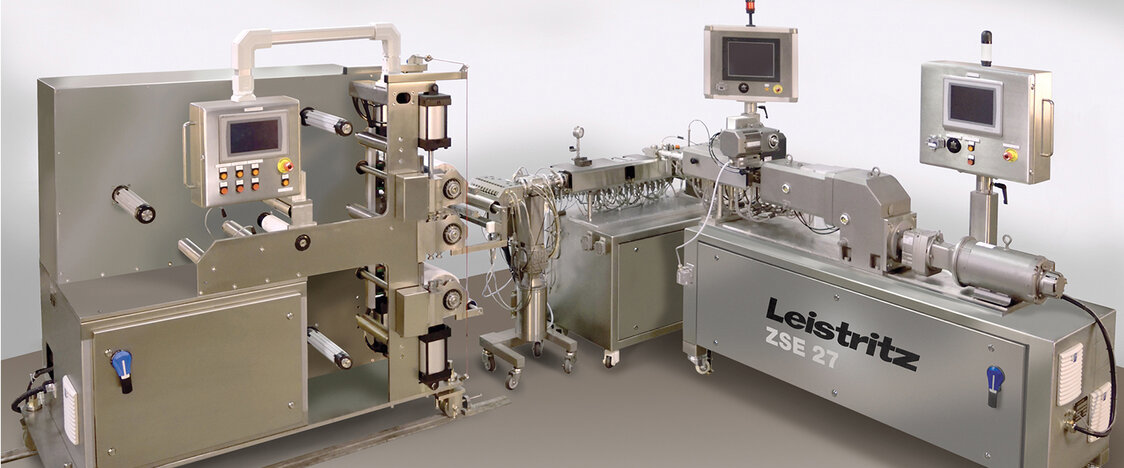

Advanced active-ingredient application systems have come to play an important role in pharmaceutical technology. Co-extrusion and the supporting subsequent aggregates offer unique advantages in the production and design of these systems.

Co-extrusion

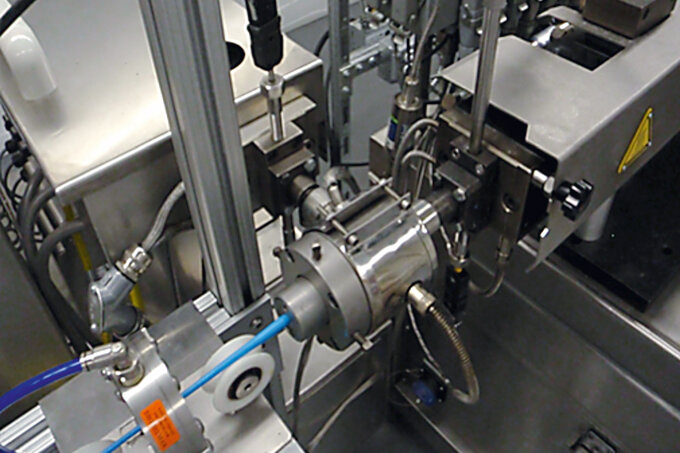

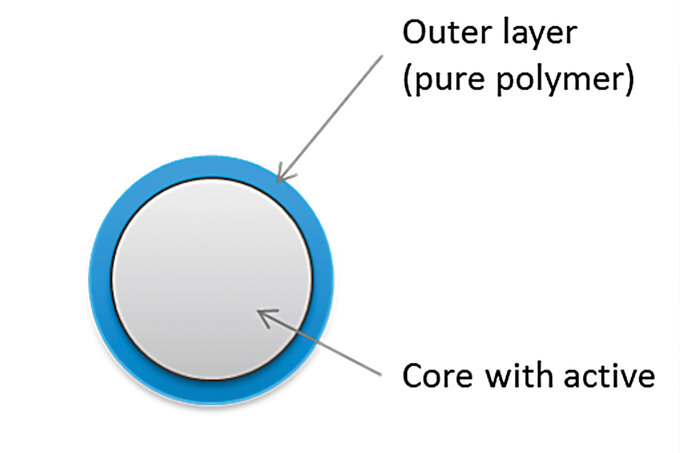

Although co-extrusion uses two extruders, the materials produced in them run through the same die. The co-rotating twin screw extruder compounds the active ingredient and the polymer. A second extruder (often a single screw extruder) shapes the outer layer, which consists of pure polymer. The outer membrane controls the drug release and has a dissolution rate of almost zero order. Since a uniform diameter must be ensured here, a melt pump is often placed between the extruder and the co-extrusion die.

After the cooling down (in the water bath), a pulling device produces the tension of the extruded product. Then the cut is made. Ultimately, the pulling device gives the magnitude of the diameter. When necessary, it is adjusted by means of a laser micrometer. The laser micrometer measures the outer diameter of the extrudate and sends the information to the pulling device, which adjusts itself accordingly. The best-known co-extruded implant is the hormone-containing Nuvaring® or Implanon®.

Co-extrusion die

Applications: vaginal ring, implants

Tube extrusion

A tube is formed by pressing the extruded polymer through a circular die, cooling it in a water bath and then cutting it or winding it up. The twin screw extruder is used when the production of medical tubes requires a compound. An example is the incorporation of silver salts. These help to prevent sepses when placing a catheter or stent. Anticoagulants can be incorporated as well to reduce blood coagulation around the appliances.

The production of the tubes on a twin screw extruder enables the modification of the metering and the reduction of raw material stocks.

The tubes can be extruded either directly from the twin screw extruder by means of a downstream melt pump, or the twin screw extruder can be used as a second extruder in a co-extrusion system. The material containing the active ingredient can be produced either as the outer layer or within the tube.

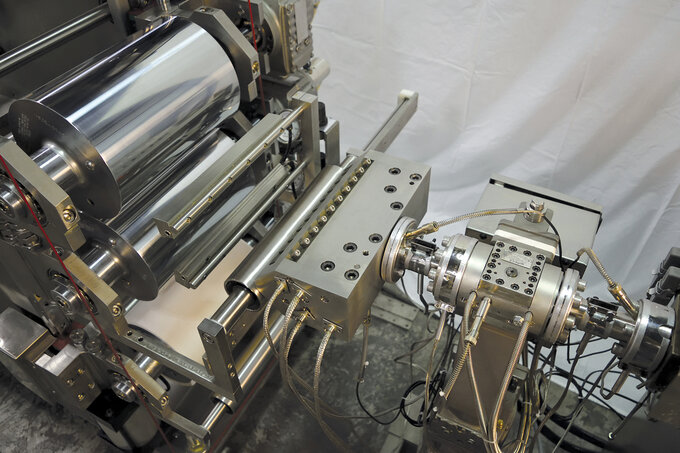

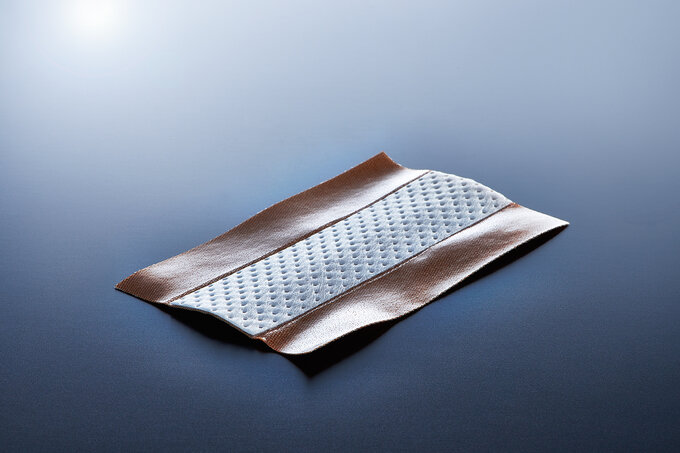

Film extrusion

Films are defined as thin layers containing one or more polymers, with or without plasticizer. They can be taken as a dosage form or be applied directly as a wound dressing with therapeutic healing effect. Laminates consist of multiple layers of films or small plates. Compared with current technologies for the production of films such as the molding process, no toxic solvents are needed in hot melt extrusion.

A special focus in film extrusion lies on the design of the die. Through a wide slot die, the melt is poured continuously onto a rotating steel roll in a thin layer. Using one or more winding stations, the film can be wound up onto a supporting material or be laminated.

Applications: Transdermal patches, sublingual films

Contact us

Leistritz Extrusion Team

Leistritz Extrusionstechnik GmbH

T+49 911 4306-610