Leistritz has long been established on the global market in the manufacturing of co-rotating twin screw extruders. After all, we have been building and optimizing extruders for more than 80 years - first for the plastics industry then also for the pharmaceutical and food industries. This is made possible not only by constant innovations and a ready ear for the users’ needs, but also by a dedicated team who bring many years of experience in this field to the table and stand behind the product with passion.

The Leistritz extruder series

The twin screw extruders from Leistritz convince with their compact and well thought-out construction, effective cooling and heating technology, and high quality and energy efficient drives. Alongside a modular barrel system, Leistritz offers a comprehensive system of various screw elements which offer great options for variation. The optimal layout of the screw geometry for each processing task is the art of our Leistritz process engineers.

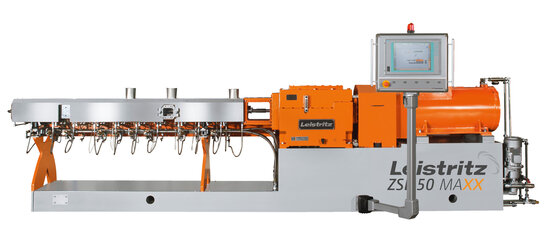

ZSE MAXX series

The ideal combination of very high specific torque (up to 15 Nm/cm³) and a large volume (OD/ID = 1.66) in one extruder - this is the feature which makes the ZSE MAXX twin screw extruder stand out. An extremely large range of processes benefits from the maximal adaptability of the ZSE MAXX since it has high process engineering relevance. As a result processors no longer have to choose between high volume or high torque machines. They can get everything in one machine.

Convincing features

- maXXvolume

high, free volume in the screw (OD/ID = 1.66) - maXXshaft

very high total torque due to patented splined shaft connection - maXXcooling

increased cooling capacity by means of optimized flow of the liquid coolant through the barrel - maXXtorque

very high available specific torque (up to 15 Nm/cm³)

Twin screw extruder with high specific torque (up to 15 Nm/cm³) and a large volume (OD/ID = 1.66)

Pharmaceutical extruders

Leistritz' extrusion systems for wet granulation and melt extrusion are globally established and are technological leaders. For the specific requirements in the sensitive pharmaceutical industry, we offer a range of extruders and corresponding additional equipment in GMP design. All machines have refined detailed engineering from a cleaning validation point of view as well as good process constancy in order to guarantee consistent product quality.

Convincing features

- closed processing unit to prevent cross contamination

- well-thought out GMP design

- state-of-the-art GxP control system

- scale-up of results from R&D to production machines

From the laboratory to the production plant - Leistritz is a technology leader in the areas of process technology, GMP design, plant engineering, and qualification.

learn more

Contact us

Leistritz Extrusion Team

Leistritz Extrusionstechnik GmbH

T+49 911 4306-610