From the recipe to the finished product

The development of new processes and formulations is an essential requirement for the future sustainability of companies. This basic research is the foundation for the constant improvement and expansion of the individual product portfolio.

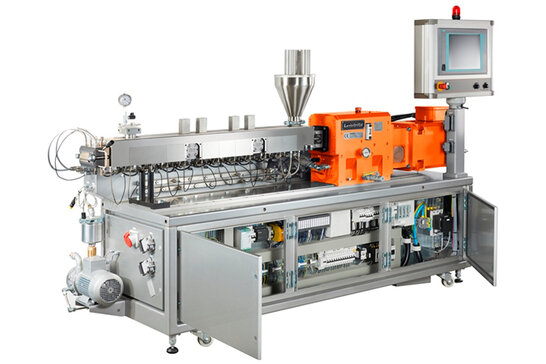

In lab extrusion, the focus is on the optimal adjustment of a process on a laboratory scale. This means that all standard processes are negotiable and the lab extruder must allow the user the same flexibility which they will later find in production systems.

With a ZSE 18 MAXX, for example, you can work with small amounts of material (with premixes from 300 g).

This comes in particularly handy when using cost-intensive raw materials (e.g. nanoclays or carbon nano tubes). The results which are achieved on these flexible machines are the key for the so-called "scale up" to larger production machines. This is possible because the modular design and the OD/ID ratio of the Leistritz lab extruder are the same as for the large ZSE MAXX machines and the geometrical ratios are thus comparable.

Lab extrusion with twin screw extruders

Contact us

Leistritz Extrusion Team

Leistritz Extrusionstechnik GmbH

T+49 911 4306-610