Meeting the challenges in plastics recycling:Innovative MFR Regulation in Recycling with the use of the Leistritz Elongational Rheometer

Constantly changing material batches from a wide variety of suppliers (feedstocks) are a major challenge for the operators of modern recycling plants. Depending on the batch, the degree of contamination by impurities, but also the melt flow rate of the products can vary greatly.

To counteract the latter, Leistritz Extrusionstechnik GmbH relies on melt flow rate control via Leistritz elongational rheometer.

The Leistritz elongational rheometer continuously determines the melt flow rate during processing to react to fluctuations of the raw material by adding additives - completely without product loss!

In a series of tests for a renowned recycling company, the MFR value for a pre-sorted post-consumer polypropylene (MFR = 11 g/10 min, 230°C, 2.16 kg) could be modified by adding a peroxide.

The use of the Leistritz elongational rheometer allows continuous determination of shear and elongational viscosity as well as melt flow rate (MFR). The MFR value was used to regulate the control command of the peroxide dosing. This allows to produce a product with a freely selectable MFR value in defined ranges.

During the series of experiments, batch changes were simulated by first adding and then removing a post-consumer PP/PE blend with a lower MFR value of 2 g/10min (230°C, 2.16 kg).

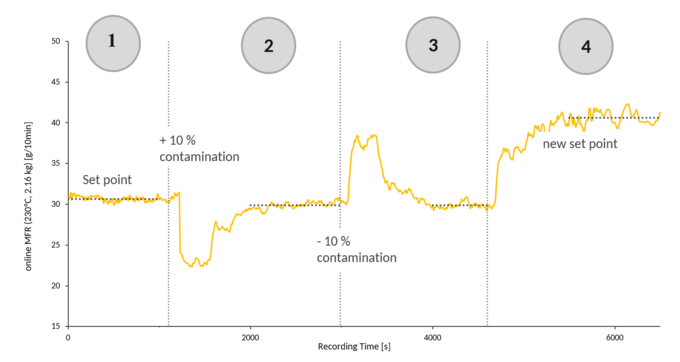

Online recording and control of the melt flow rate with and without impurities

The figure shows the melt flow rate measured online, which was set to a target value of 30 g/10 min in section ①.

By adding and then removing 10% contamination in sections ② and ③, a shift to lower or higher MFR values can be observed first.

Adding an impurity as a step response simulates a batch change with possibly different product properties. Subsequently, the set target value of 30 g/10min could be reached again. In section ④, a setpoint step change to 40 g/10 min was performed. Here, too, the controller was successfully used to automatically adjust the melt flow rate.

When comparing the MFR values measured on- and offline, a deviation of less than 5% from the absolute value was found. In this case, the use of the Leistritz elongational rheometer as a smart sensor enables the reduction of product waste and contributes to the increase of product quality.

Would you like to find out more about MFR regulation?

Then contact us!

Our experts will be happy to advise you!